CRW Finishing Inc. is a proud distributor of Hammond Roto-Finish High Energy/Specialty Finishing Equipment. Our equipment offers up to 50% cycle time reduction over conventional vibratory machines. The design of the bowl and drive in conventional machines create “bounce” within the media that translates into air time between the media and part. Call us today to discuss your specific requirements.

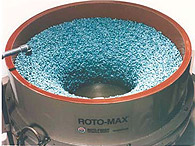

Hammond Roto-Finish’s Roto-Max® and Roto-Max® Revolution are high speed, high energy finishing systems for deburring, surface improvements, descaling and finishing parts made of metal, rubber or plastic. Roto-Max® reduces vibratory process cycles for deburring hard metals, rough forgings and castings to the finishing of jewelry, hardware, and medical implants.

- Centrifugal action is approximately 15 times faster than traditional vibratory finishing.

- Cooler, more cushioned mass reduces part damage.

- Unique seal design reduces intrusion of smaller parts and media, thus extends service life of rotor.

- Wider range of surface finishes attainable with a given media.

- Provides high energy deburring, descaling and improving surface finishes.

- Choice of smooth or ribbed polyurethane lining.

- Electrically controlled compound solution system.

- Programmable controls

Roto-Max® is available in 1, 2, 3, and 6 cubic foot models.

Roto Max® Revolution (with Process/Unload/Reload), is available in 2, 3, 6, and larger cubic foot capacity

INTERNAL FINISHING ON PREMIUM PARTS

Our multivibrators each have three high-speed imbalance drives that allow you to vary the position and rotation direction. This enables extremely small vibration amplitudes, ensuring high surface quality for your workpieces – even on difficult-to-reach areas. Delicate bars are protected, the workpiece contours are retained, and even small-diameter boreholes can be processed internally.

CRW Finishing offers Walter Trowel’s Model Range Multivibrator MV Equipment. HIGHLY VERSATILE AND EFFICIENT The vibrators of the MV model range are the ideal machines for fine grinding and polishing of delicate workpieces with intricate shapes and contours.

THE BENEFITS AT A GLANCE

- High reproducibility

- Uniform finish

- Wet process with water and compound

- Suitable for 24-hour operation

- Low fitting and auxiliary process times with electromagnetic clamping device

630.495.4994

630.495.4994