Media-Blasting

Impact blast cleaning removes surface contamination, burrs, and feathered edges, from a broad spectrum of parts. Choosing the right blast media depends on the desired finish and application.

Abrasives-Aluminum Oxide

Aluminum oxide is a sharp long lasting abrasive used for finishing and cleaning. It has a fast-cutting action which minimizes damage to thin materials. It is durable and can be recycled many times.

Aluminum oxide is a high-quality abrasive that does not dull quickly. It leaves a smooth flat, coarse-textured finish and is longer lasting and considerably more aggressive than Glass Beads

Applications Include:

- Cleaning Engine Heads

- Valves

- Pistons

- Turbine Blades

| Standard US Mesh Sizes | |

| 12 | 80* |

| 16 | 100 |

| 20 | 120* |

| 24 | 150 |

| 30 | 180* |

| 36 | 220 |

| 46 | 240 |

| 54 | 280 |

| 60 | |

*Typically Stocked Item

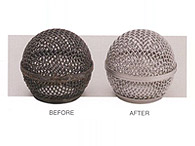

Glass Beads

Glass Beads smoothly blends away surface defects. A finer, smoother non-glare finish is achieved with smaller spheres, while larger spheres produce a more textured finish.

- Special effects are easily achieved through simple masking before the blasting process.

- Finish is reproducible, time after time.

- Improves lubrication

- Improves adhesion capabilities

Steel Shot/Steel Grit

Steel shot and steel grit are reclaimable Medias used mainly in blast cabinets.

Steel Shot is ideal for peening applications to impart a clean, smooth and polished finish.

Steel Grit is an angular carbon steel designed for quick and effective removal of surface contaminants from metals.

Steel Shot or Steel Grit Applications include:

- Shot Blasting

- Shot Peening

- Cutting

S.A.E. Sizes Available

| Shot | Grit |

| S780 | G10 |

| S660 | G12 |

| S550 | G14 |

| S460 | G16 |

| S390 | G18 |

| S330 | G25 |

| S280 | G40 |

| S230 | G50 |

| S170 | G80 |

| S110 | G120 |

| S70 |

Packaging Options:

- Available in standard 55 gallon steel drums

- (2000#/drum)

- 50# kraft paper bags (40 in a pallet box)

- supersacs (1-2 tons).

Save on your cleaning costs by purchasing conditioned steel shot and grit! No scrap surcharges, no pallet/drum charges.

Call a CRW representative today to discuss choosing the best blast media for your specific application.

630.495.4994

630.495.4994